Everyone, from food and drink retailers to brands and packaging manufacturers, has been grappling with the growing issue of plastic waste and pollution. Some are trying out new materials and different forms of recyclable plastics, others have taken food out of their packaging entirely. While some trials have failed, other initiatives have excelled.

Here are some of the trailblazers tackling the plastic waste problem head-on

The inventor who turned fish guts into bioplastic

“A good design is something that bridges the gap between behaviours, business and our planet,” says engineering graduate Lucy Hughes, who last month walked away with the James Dyson design award for her creation of bioplastic MarinaTex.

Having lived by the sea and witnessed marine pollution first hand, Hughes set about creating a sustainable alternative to single-use plastic. She opted to avoid virgin materials in favour of making use of an existing and plentiful waste stream: the 172,000 tonnes of fish waste generated by UK processing plants each year.

Hughes began experimenting with the waste skin and guts, binding them together using the gelatinous substance scraped from the cell walls of red algae. The final result took no less than 100 experiments, most on the kitchen stove of her student digs.

The bioplastic Hughes has created is a translucent and flexible sheet material, stronger than an average plastic bag but capable of home composting in between four to six weeks. That makes it sufficiently stable for industry to use in its supply chain, but sufficiently biodegradable (without industrial processing required) that it limits its chances of being spotted in a David Attenborough documentary any time soon.

Looping in a circular recovery system

Set to launch in the UK early next year, Loop is the brainchild of recycling firm TerraCycle and a number of major fmcg brands including P&G, Nestlé and PepsiCo. The idea is to create a closed loop for food containers that allows consumers to buy household brands in refillable packaging that will be collected, cleaned and reused.

In May, France became the first country to pilot the scheme, supported by retailer Carrefour, with consumers invited to sign up to the shopping platform and buy products from 25 major brands in durable refillable packaging. The selection currently includes the likes of Quaker’s wholegrain mix in a 500g aluminium tin and Tropicana juice in a glass bottle that can withstand up to 80 cycles, alongside a number of private-label products, such as dried lentils and beans, instant coffee and dried pasta. Consumers pay a small deposit for the packaging when they order, which is returned once its collected.

“Waste is a worldwide global crisis that has been growing for over a half a century,” says Tom Szaky, founder and CEO of TerraCycle and Loop. “Loop has been designed to address this issue. For the first time, major brands, along with sustainable resource management company Suez have been working together to create a convenient way to enjoy a wide range of products, that will be delivered in customised, brand-specific durable packaging.”

With the trial now up and running in the US too, where the likes of Purina petfood and Häagen-Dazs have been added to the mix, the scheme is set to reach the UK in 2020.

Halo is first compostable coffee capsule

Since Nespresso pods launched in the early 1990s, sales of single-use capsules have soared. But finding a green alternative that maintained the freshness of the coffee and was sufficiently durable was trickier. Solutions were made from bio-plastic and/or compostable only by industrial means.

Then in 2017, UK-based Halo developed the planet’s first 100% home-compostable pod made from sugar cane and paper pulp, which can also be thrown in with food waste. In late 2018 the range of pods was further enhanced via a £1.5m investment in a design revamp, which also resulted in the outer packaging becoming eco-friendly (as well as adding three new flavour variants).

The launch has proved a catalyst. Costa and Lost Sheep added compostable pods earlier this year, while Lavazza is set to launch its Eco Caps next month.

Zero-plastic packaging for food safety

With even ostensibly sustainable food and drink packaging often relying on protective layers of plastic for food safety and hygiene, the demand for alternatives is on the rise.

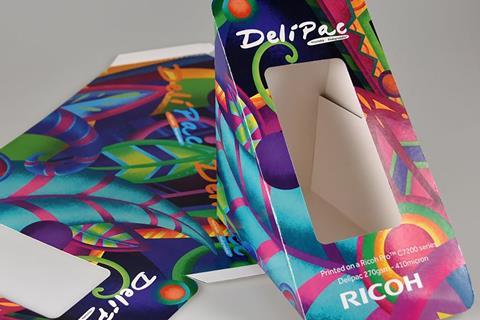

Enter Delipac, which says it has created one such alternative: a ‘zero-plastic sustainable barrier packaging that is 100% recyclable, biodegradable and compostable’.

The material has applications across fast food, frozen foods, ready meals or even airline food, it says.

“There is a global drive to eliminate as much plastic as we can from our lives and one of the biggest issues at the moment is the application of packaging for single-use food and drink products,” explains Paul Spring, CEO of Delipac. “This is where our innovation comes into its own.

“Delipac can be recycled without having to employ specialist plants, it biodegrades after 12 to 25 weeks when in landfill and is naturally compostable.”

Instead of a plastic coating, Delipac relies on a water-based coating layered between the food and its packaging board, which ‘ensures freshness’ while ditching the need for any kind of plastic.

“It has taken us seven years to develop and prove the performance,” adds Spring. “Initial market interest has been significant, especially with mainstream brands keen to do their bit by taking plastic out of their packaging.”

In fact, the ‘robust grease and moisture barrier’ can be easily used by brands as a surfacing to apply ‘standout corporate branding’ and promotional offers, says Delipac.

The edible water bottle

Talk of an edible alternative to plastic bottles has been around for many years. But this year the concept is one step closer to reality after a joint project between startup Skipping Rocks Lab and Lucozade Ribena Suntory (LRS) received government backing.

The startup first made headlines way back in 2013 with a viral video of its edible and biodegradable alternative to plastic bottles, Ooho. The material, called Notpla, is made by combining seaweed and other plants and can be eaten along with its liquid contents.

Then this year the startup partnered with LRS to fill its capsules with Lucozade Sport Orange and hand them out to runners at the London Marathon – a demonstration of their commercial potential that saw Innovate UK invest £300k. The funding will be used to create a machine capable of being installed in gyms, restaurants or coffee shops and manufacturing up to 3,000 Oohos per day.

The compostable crisp packet

Just as crisp behemoth Walkers was left red-raced when Royal Mail had to ask environmental activists to stop posting its empty crisp packets back in protest at the use of plastic, tiny startup Two Farmers was quietly launching its own fully compostable solution.

The fully biodegradable crisp packet created by the two Herefordshire farmers reportedly looks and feels just like plastic but can be chucked on the garden compost heap to degrade in around 26 weeks.

“We looked at boxes and tins before the fully compostable crisp packet materialised,” says co-founder Sean Mason. But “we now have the perfect solution – our packets are made of sustainably grown eucalyptus wood fibres with vegetable ink printing and will fully biodegrade in your home compost in under 26 weeks.”

100% zero-waste supermarket

Waitrose might have caused quite the stir in June when it unveiled its Unpacked concept store in Oxford, but its efforts look positively conservative in comparison to Clean Kilo in Birmingham.

Launched in 2018, the small supermarket hasn’t simply experimented with packaging-free elements but instead stripped out all packaging (and waste) from the store, with customers asked to bring their own reusable shopping bags plus refillable containers for everything they want to buy.

So successful has the store been that its co-founders Jeanette Wong and Tom Pell opened a second outlet in the city in August.

“We have had an incredible first year of business,” says Wong. “It is tremendously rewarding to know that we are offering people an accessible way of cutting down on plastic.”

Making plastic a force for social good

In 2018 Eat Natural became the first fmcg brand to partner with Plastic Bank, a scheme that allows businesses to offset their plastic use much as a company might offset its carbon emissions.

The cereal bar brand says the partnership allows it to offset 115 tonnes of plastic, making it effectively plastic-neutral. The project is also supported by Aldi’s German retail business and Evian.

The scheme works in two ways. On the one hand it turns plastic into an economic resource rather than a source of pollution, recruiting people in some of the world’s poorest countries, such as Brazil, Haiti and the Philippines, to collect discarded plastic that would otherwise be waste, and deliver it in exchange for cash, healthcare and education. This collected plastic is deemed ‘social plastic’ and used by partner brands to manufacture new products. Plastic Bank can provide brands with processed pellet or flake feedstock of PET, HDPE, LDPE, and PP.

Alternatively, companies and individuals can also become plastic-neutral through simple cash donations that pay for the recovery of a certain volume of this social plastic. This is a good solution for organisations which are unable to use social plastic, or those that require more modest volumes Collection credits guarantee the removal of 1kg of ocean-bound plastic.

“In an ambient food business like ours, plastic is currently an unavoidable entity,” says Eat Natural co-founder Praveen Vijh. “But we are committed to ensuring that we are doing as much as we can to protect our precious planet.”

The viral straw made from seaweed

Who knew a straw could wield such influence? No less than 25,000 people follow US startup Loliware on Instagram thanks to its carefully curated feed of photogenic millennials sipping soft drinks and iced coffees through the company’s own biodegradable (and edible) straws.

Founded in 2015, the startup has harnessed what it calls ‘the world’s leading seaweed technology’ to come up with an alternative to single-use plastic made entirely from food grade materials.

Its first product, The Straw of the Future, launched into the US in March following a (rather humble) $30k campaign on Kickstarter and claims to be able to withstand 18 hours of continuous use. Fruit flavours can even be infused into the material to make it edible after you’ve finished drinking. The founders say the straws will be available in the UK next year.

The stock served in a can

As of this month, Tesco shoppers will be able to switch plastic pouches of cooking stock for eco-friendly aluminium cans thanks to innovation by fine foods brand Potts.

The brand estimates it could save up to 1.1 million tonnes of plastic per year by switching a selection of its readymade stocks into the new 100% recyclable packaging. The 500ml can requires lower energy input, says the brand, and can be recycled an infinite amount of times in a closed loop process.

Based on a standard drinks can – right down to the ‘tsst’ sound when it opens thanks to the release of nitrogen when the seal is broken – the innovation is the result of considerable investment, adds the brand, but will be sold at the same price as its plastic pouches. It will be on sale at Tesco alone for the first six months.

If successful the brand hopes to roll the format out more widely across both its retail partners and its portfolio.

No comments yet